Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

DM Series

In the flip chip module display, the integrated circuit is flipped upside down, and the solder bumps are used to make the direct electrical and mechanical connections to the substrate. This allows for a more compact and efficient design, with a shorter electrical path and improved thermal performance. Additionally, the direct connection enables higher data transfer rates and reduces signal loss, resulting in better overall performance, thus the display effect of this series products.

Unlike traditional wire bonding methods, flip chip module displays offer a range of distinctive benefits that drive greater efficiency, performance, and design flexibility. The direct chip-to-substrate connection reduces the electrical path, resulting in enhanced signal integrity, faster data transfer rates, and diminished signal loss. This, in turn, contributes to improved overall display performance. Additionally, the flip chip module approach enables more compact and efficient designs while supporting superior thermal management. The direct connection significantly reduces thermal resistance, allowing for efficient heat dissipation and promoting long-term reliability.

With its advanced packaging technology, flip chip module displays are utilized in various display applications. Leveraging these displays affords numerous advantages, including increased pixel density, faster response times, and superior power efficiency. Moreover, the flip chip module architecture facilitates the development of flexible and curved displays, ensuring greater design versatility and paving the way for innovative product designs.

In summary, the flip chip module represents a groundbreaking innovation in electronic packaging, offering a range of benefits such as improved electrical performance, enhanced thermal management, and design flexibility. As a result, this technology has become an integral part of the display industry, driving advancements in various electronic devices and empowering the development of state-of-the-art display solutions.

Original Factory

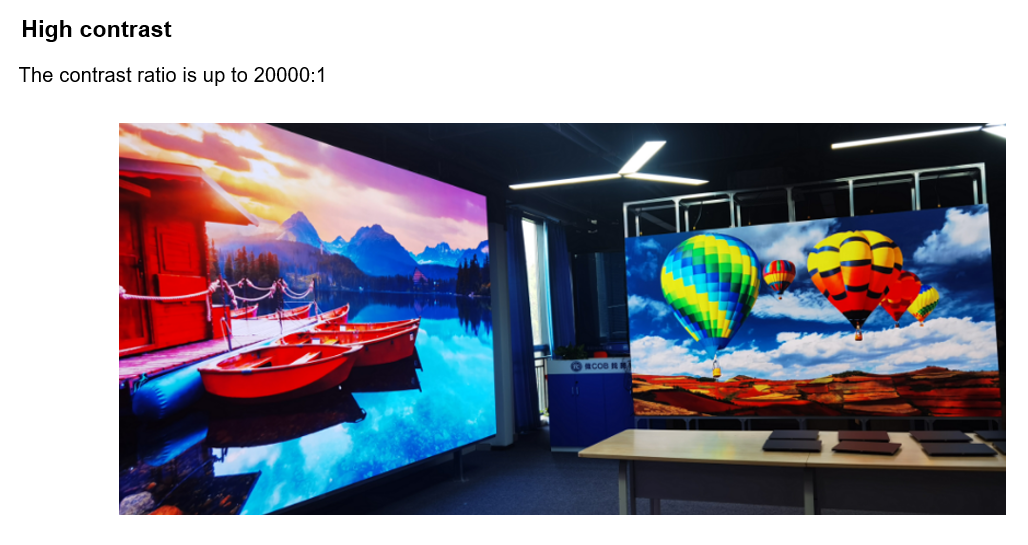

- Contrast ratio as high as 100000:1, the image is clearer and the colors are more vivid

- New packaging technology, using full flip chip COB packaging

- Maximum power consumption is as low as 350w/m, saving energy and electricity

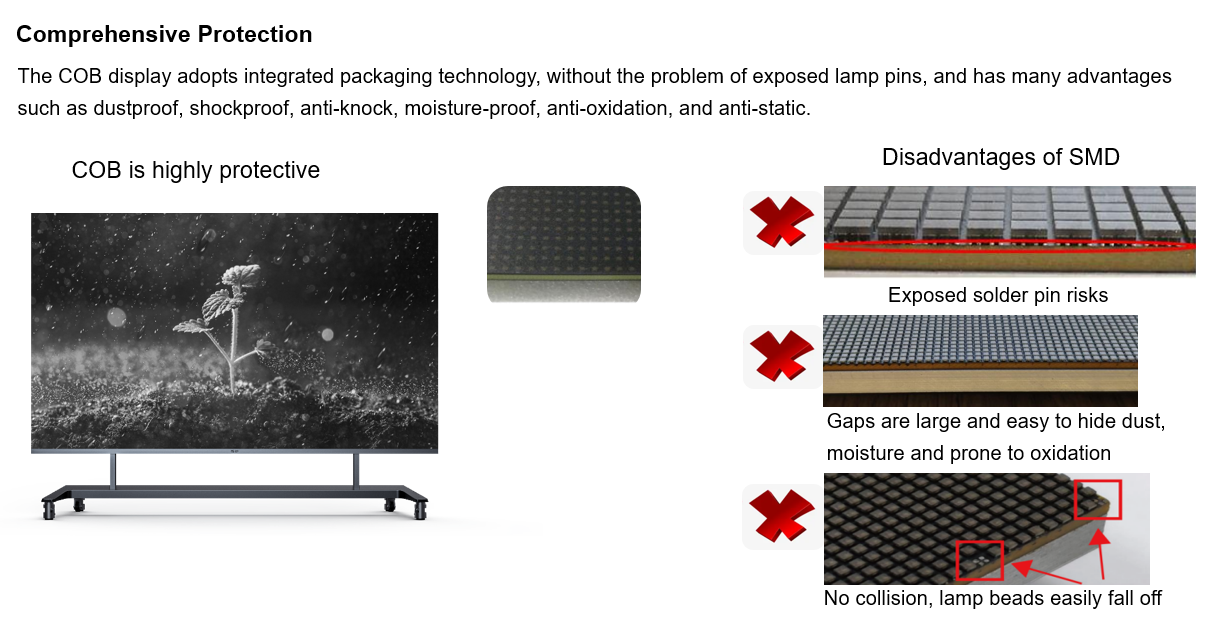

- High protection, moisture-proof, dust-proof and bump-proof

- Breaking through the limitations of traditional cabinets, it supports arbitrary splicing in units of modules

- 16:9 golden ratio, supports full 2K/4K/8K display, point-to-point display

- Support various installation methods, such as wall mounting, ceiling mounting, and floor mounting

Applications

- Business Centers: The flip chip COB LED module display can be used in conference rooms, reception areas, and lobbies to showcase important information, advertisements, or even live feeds from events. Its high resolution and vibrant colors ensure a visually appealing experience for clients and visitors

- Exhibitions: The compact size and high brightness of the flip chip COB LED module display make it perfect for exhibition booths. It can effectively attract attention and engage attendees with dynamic content, product demonstrations, and interactive experiences

- Education: Schools, colleges, and universities can utilize flip chip COB LED module displays for digital signage, announcements, and wayfinding purposes. It can also be integrated with interactive features to create immersive learning environments

- Medical Care: In healthcare facilities, the flip chip COB LED module display can be used for patient education, waiting area entertainment, or as a tool for medical professionals to showcase medical imagery and procedures. Its high resolution ensures clear and detailed visuals, which can be critical in medical settings

- Security Monitoring: The flip chip COB LED module display can be integrated into security monitoring systems to display live feeds from surveillance cameras. Its high brightness and wide viewing angles ensure that security personnel can effectively monitor multiple areas simultaneously

|

Model |

TC-DM0.9 |

TC-DM1.2 |

TC-DM1.5 |

||

|

Pixel Pitch |

P0.9375 |

P1.25 |

P1.5625 |

||

|

Pixel Density (pixel/m2) |

1137777 |

640000 |

409600 |

||

|

Packaging Method |

Flip chip COB |

||||

|

Module Size |

300*168.75mm |

||||

|

Module Resolution (pixel) |

320*180 |

240*135 |

192*168 |

||

|

Module Back Housing Material |

Aluminum |

||||

|

Module Weight (kg/pcs) |

0.5 |

||||

|

Flash Correction Storage |

support |

||||

|

White Balance Brightness |

600nits |

||||

|

Viewing Angle |

Horizontal 170°, Vertical 170° |

||||

|

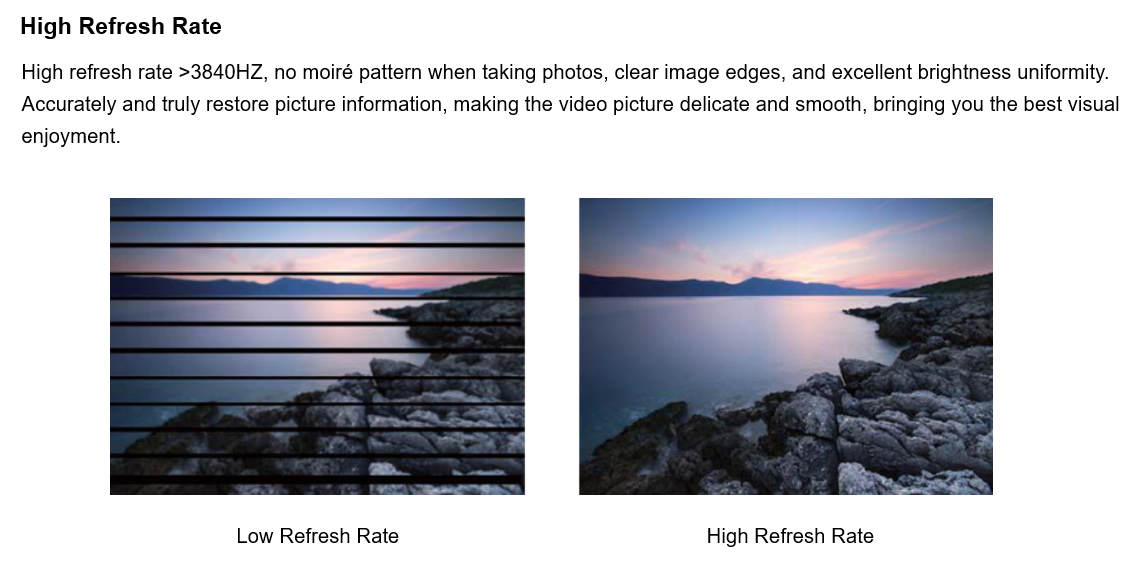

Refresh Rate(Hz) |

3840 |

||||

|

Contrast Ratio |

10000:1 |

||||

|

Color Temperature(K) |

2000-10000 adjustable |

||||

|

Luminance Uniformity |

97% |

||||

|

Chromaticity Uniformity |

±0.003Cx,Cy |

||||

|

Luminance/Chromaticity Correction |

support |

||||

|

Display Unit Input Voltage |

AC 100-240V 50/60Hz |

||||

|

Working Voltage (V) |

DC2.8/3.8 |

DC 3.8 |

DC 3.8 |

||

|

Max. Power (w/pcs) |

≤18 |

||||

|

Module Signal Interface |

HUB320 |

||||

|

IP Grade |

IP54 |

||||

|

Working Temperature and Humidity Range |

-10℃-+40℃/10%RH-9O%RH |

||||

|

Storage Temperature and Humidity Range |

- 40℃-+60℃/10%RH-90%RH |

||||

|

Service Life (hours) |

100000 |

||||

|

Certification |

CCC |

||||

Project Cases